Phone Number :

07 07, 2023

In the manufacturing of household appliances, ensuring the safety and reliability of electrical components is of paramount importance. One vital aspect is testing and verifying the insulation performance of PVC hoses used in these appliances. This article examines the various methods and procedures employed to assess the insulation capabilities of PVC hoses, ensuring the safety and functionality of the final product.

1. Voltage Withstand Test:

The voltage withstand test involves placing a specific voltage across the PVC hose for a predetermined time. This test is conducted to evaluate the integrity of the insulation against high voltages. The hose is considered to have passed the test if it can withstand the applied voltage without electrical breakdown or arcing.

2. Insulation Resistance Test:

The insulation resistance test measures the electrical resistance of the PVC hose. A high resistance value indicates good insulation properties. This test is performed by applying a known voltage to the hose and measuring the resulting current. A lower current indicates a better-insulated hose.

3. Dielectric Test:

The dielectric strength test assesses the ability of the insulation material to resist electric stress without experiencing electrical breakdown. By applying an increasing voltage, the test measures the voltage at which breakdown occurs. A higher dielectric strength signifies better insulation performance.

1. Material Selection:

The type and quality of the PVC material used in the hose significantly impact its insulation performance. Choosing high-quality PVC materials that have excellent electrical properties ensures better insulation and a longer service life.

2. Thickness and Design:

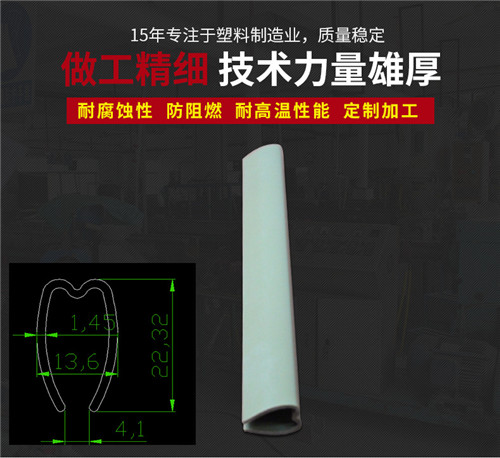

The thickness and design of the PVC hose also affect its insulation abilities. A thicker hose wall provides better insulation, while a well-designed hose can reduce the risk of cracks or weak points that compromise insulation performance.

3. Environmental Factors:

The operating conditions and environment of household appliances can influence the insulation performance of PVC hoses. Extreme temperatures, humidity, and exposure to chemicals or oils can degrade the insulation properties over time. Therefore, thorough testing is necessary to evaluate the hose's insulation performance under various conditions.

Ensuring the insulation performance of PVC hoses in household appliance manufacturing is crucial for the safety and reliability of the final products. Through voltage withstand testing, insulation resistance testing, and dielectric testing, manufacturers can verify the insulation capabilities of PVC hoses and identify any potential issues. Factors such as material selection, thickness and design, and environmental factors all play a significant role in determining the insulation performance. By conducting rigorous testing and verification procedures, manufacturers can produce appliances with superior insulation that meet the highest safety standards.