Phone Number :

07 05, 2023

PVC hoses play a crucial role in the safe and efficient transportation of chemicals. To ensure that these hoses are reliable and durable in such demanding conditions, extensive research is necessary. This article focuses on exploring various factors that contribute to the reliability and durability of PVC hoses in chemical transportation.

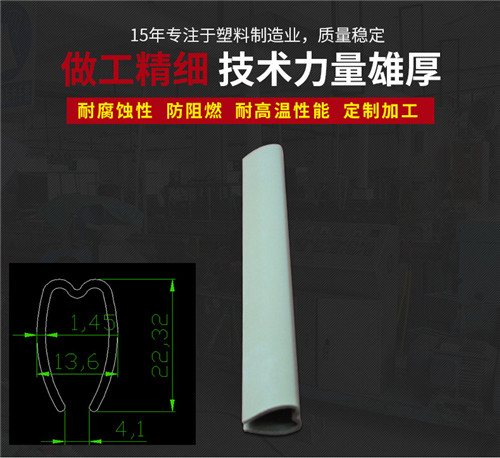

The choice of materials and their composition significantly affects the reliability and durability of PVC hoses in chemical transportation. Extensive research is being conducted to identify the most suitable polymers, plasticizers, and reinforcement materials for the hose construction.

The ideal material composition should possess excellent chemical resistance to withstand the corrosive nature of transported chemicals. It should also exhibit superior mechanical properties, such as high tensile strength, flexibility, and resistance to abrasion. Researchers are exploring new additives and composite structures to enhance these properties.

Developing standardized testing methods is vital to assess the reliability and durability of PVC hoses in chemical transportation. Researchers are working towards establishing comprehensive testing protocols to evaluate factors like burst pressure, resistance to chemical permeation, and temperature endurance.

One significant area of research involves simulating real-world conditions in laboratories. Accelerated aging tests, such as exposure to extreme temperatures, chemicals, and pressure cycles, help determine the long-term performance of PVC hoses. These tests aid in estimating the lifespan and predicting any potential failure modes.

Designing PVC hoses to withstand chemical transportation requires meticulous engineering. Researchers are focusing on optimizing hose designs to minimize stress concentrations, prevent material degradation, and ensure uniform chemical flow.

Additionally, innovative manufacturing techniques like co-extrusion and cross-linking are being explored to enhance the reliability and durability of PVC hoses. Co-extrusion enables the combination of different materials, providing tailored properties for specific chemical applications. Cross-linking techniques improve the mechanical strength and chemical resistance of PVC hoses.

In conclusion, extensive research is underway to enhance the reliability and durability of PVC hoses for chemical transportation. By carefully selecting materials, establishing standardized testing methods, and optimizing product design, significant advancements can be made. This research ultimately aims to ensure the safety and efficiency of chemical transportation while extending PVC hose lifespan.