Phone Number :

02 20, 2024

When it comes to ensuring tight and reliable seals in various applications, the rubber sealed loop has proven to be a versatile and dependable solution. With its unique design and properties, this sealing mechanism offers numerous benefits and has found applications in a wide range of industries. In this article, we will explore the features and advantages of the rubber sealed loop, as well as its various applications in different sectors.

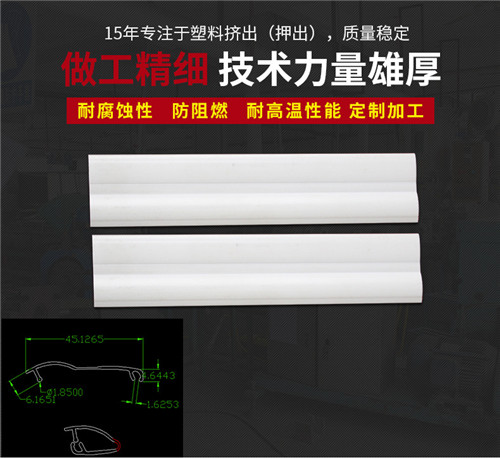

The rubber sealed loop is a specially engineered sealing mechanism that consists of a loop-shaped rubber gasket enclosed within a metal or plastic housing. The gasket is made of high-quality rubber materials, such as EPDM, silicone, or neoprene, which possess excellent resistance to temperature, pressure, and environmental factors. The loop design ensures a uniform distribution of sealing force, enabling it to provide a reliable and consistent seal.

One of the key advantages of the rubber sealed loop is its superior sealing performance. The high-quality rubber gasket creates an effective barrier to prevent the leakage of liquids, gases, and other substances. It offers exceptional compression and rebound characteristics, allowing it to maintain a tight seal even under varying conditions. Additionally, the rubber material can adapt to irregular surfaces, ensuring a complete and leak-free seal.

The rubber sealed loop finds extensive applications in various industries due to its versatile nature. In the automotive sector, it is commonly used for sealing engine components, such as cylinder heads, intake manifolds, and valve covers. In the plumbing industry, rubber sealed loops are employed for sealing pipes, fittings, and joints to prevent water leakage. Moreover, their resistance to chemicals and extreme temperatures makes them suitable for use in chemical processing, oil and gas, and food processing industries.

Compared to traditional sealing methods, the rubber sealed loop offers several advantages. Its loop design allows for easy installation and removal, reducing assembly time and labor costs. The rubber material provides a more forgiving seal, accommodating slight dimensional variations and surface imperfections. Furthermore, the rubber sealed loop offers excellent durability, withstanding harsh operating conditions and maintaining its sealing performance over a long service life.

The rubber sealed loop continues to evolve with advancements in material science and engineering. Ongoing research and development efforts aim to enhance its sealing properties, such as increased temperature and chemical resistance. Additionally, the versatility of the rubber sealed loop opens up possibilities for new applications, including renewable energy systems, aerospace technologies, and medical devices.

In conclusion, the rubber sealed loop is a reliable and versatile sealing solution with a wide range of applications. Its unique design, superior sealing performance, and advantages over traditional methods make it a preferred choice in various industries. As technology advances, we can expect further improvements and expanded applications for this innovative sealing mechanism.