Phone Number :

10 13, 2023

Rectangular tubes and square tubes are commonly used structural elements in various industries. Although they may appear similar, there are significant differences in their shape, properties, and applications. In this article, we will delve into the disparities between rectangular tubes and square tubes, highlighting their distinct characteristics and purposes.

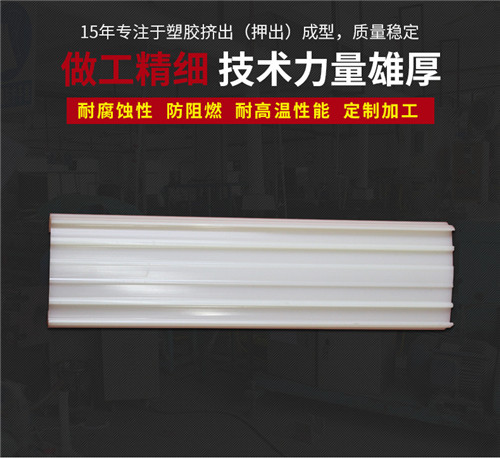

Rectangular tubes, as the name suggests, have a rectangular cross-section with sharp 90-degree corners. They possess two long sides and two short sides, providing a wider range of dimensions. The length-to-width ratio of rectangular tubes varies, allowing for a greater degree of flexibility in design.

On the other hand, square tubes have an equal width and length, forming a perfect square cross-section. The corners of square tubes are also right angles, akin to rectangular tubes. Unlike rectangular tubes, square tubes offer limited size options due to their symmetrical dimensions.

Despite their similarities in shape, rectangular and square tubes differ in their structural properties. The geometry of rectangular tubes allows for higher torsional stiffness and bending resistance compared to square tubes. The larger surface area of rectangular tubes provides increased contact points and greater structural stability.

Alternatively, square tubes excel in resisting torsion due to their symmetrical design. The equal dimensions and closed shape offer uniform strength, making square tubes more suitable for applications where torsional forces are predominant.

Rectangular tubes and square tubes find applications in various industries due to their unique properties.

Rectangular tubes are commonly used in construction, architecture, and engineering projects that require stability, load-bearing capabilities, and resistance to bending. Their larger surface area is advantageous for mounting brackets, frames, and supports. Additionally, the wider range of dimensions allows for diverse applications in machinery, manufacturing equipment, and transportation industries.

Square tubes, on the other hand, are preferred in applications that involve torsional stress or when symmetry is crucial. They find extensive use in the automotive, aerospace, and furniture industries, where lightweight structures and torsional rigidity are vital. Furthermore, square tubes are popular in the fabrication of ornamental products, such as gates, handrails, and decorative frames.

In summary, while rectangular tubes and square tubes share similarities in their sharp corners and right angles, they have distinct variations in shape, properties, and applications. Rectangular tubes offer a wide range of dimensions, providing flexibility in design, whereas square tubes offer symmetrical dimensions and excel in torsional resistance. Understanding the disparities between these two tube shapes is crucial for selecting the appropriate choice for specific applications. Whether it's supporting structures or addressing torsional stress, both rectangular and square tubes play indispensable roles in the construction and manufacturing industries.