Phone Number :

08 17, 2023

In today's fast-paced world, the demand for efficient cable management in various industries is on the rise. When it comes to organizing and protecting cables, a cable tray model plays a crucial role. It provides a structural system for routing and supporting cables, ensuring safety and ease of maintenance.

A cable tray model offers several benefits. Firstly, it allows for easy installation and expansion of cable systems. With its modular design, cables can be added or removed with minimum disruption. Additionally, the cable tray model provides superior ventilation, preventing heat buildup and reducing the risk of cable damage.

Another key advantage of using a cable tray model is cost savings. Compared to traditional wiring systems, cable trays are more cost-effective, both in terms of installation and maintenance. Their sturdy construction ensures longevity, reducing the need for frequent replacements and repairs.

Cable tray models also enhance safety. By keeping cables organized and off the floor, the risk of accidents such as tripping and electrical hazards is significantly reduced. Moreover, cable trays protect cables from external elements such as moisture, chemicals, and dust, ensuring the longevity and reliable performance of the cables.

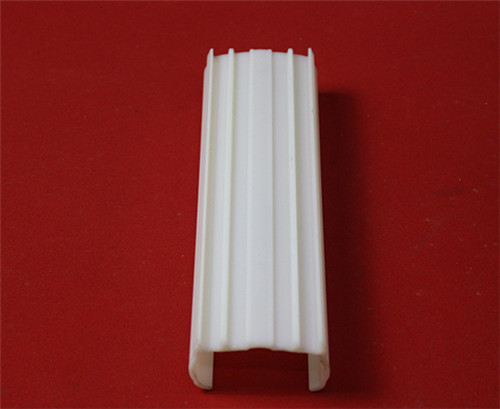

Creating an effective cable tray model requires attention to detail and a thorough understanding of the cable management requirements. There are different types of cable trays available, including ladder, solid-bottom, and wire mesh trays. The choice depends on factors such as cable load, location, environment, and aesthetic preferences.

While designing a cable tray model, it's crucial to consider factors like cable capacity, bend radius, and cross-sectional area. Calculating the load capacity is vital to ensure the tray can withstand the weight of the cables without deformation or structural compromise. Additionally, designing appropriate bends and transitions ensures the optimal cable performance and longevity.

It is also essential to choose the right materials for the cable tray model. Common materials include steel, aluminum, and fiberglass. Stainless steel is preferred for corrosive environments, while aluminum is lightweight and suitable for less demanding applications. Fiberglass offers excellent chemical resistance and is ideal for industries with corrosive atmospheres.

In conclusion, the design and implementation of a cable tray model are fundamental for efficient cable management. It offers numerous benefits, including easy installation, cost savings, enhanced safety, and protection of cables. By considering factors such as cable load, environment, and material selection, a well-designed cable tray model ensures streamlined cable management and promotes the overall productivity of various industries.