Phone Number :

07 28, 2023

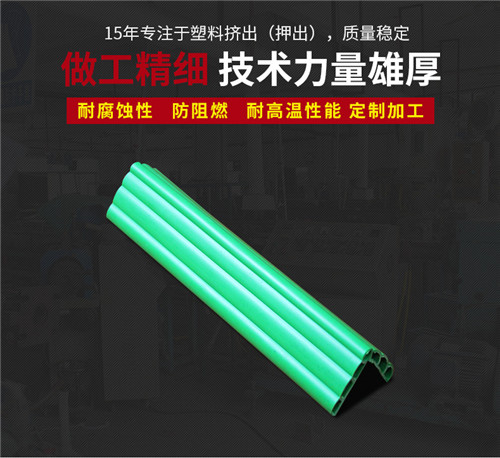

Anti-collision strips play a critical role in protecting vehicles from potential damages during collisions. These strips are widely used in the automotive industry and are designed to absorb impacts, reducing the force transferred to the vehicle. Understanding the manufacturing process and material selection principle of these anti-collision strips is crucial in ensuring their effectiveness.

The manufacturing process of anti-collision strips involves several key steps:

The first step is to select the appropriate materials for the anti-collision strips. These materials should possess excellent impact resistance, durability, and flexibility. Commonly used materials include rubber, thermoplastics, and composite materials. The selected materials are then prepared by cutting them into suitable sizes and shapes.

After the material preparation, the molding process takes place. The selected materials are placed into molds, which are specially designed to create the desired shape and structure of the anti-collision strips. These molds are subjected to heat and pressure to facilitate the material's bonding and shaping.

Once the molding is complete, the anti-collision strips undergo surface treatment. This treatment involves the application of various coatings or finishes to enhance the strips' durability, resistance to external influences, and appearance. Surface treatment techniques may include painting, electroplating, or powder coating, depending on the desired aesthetic and functional requirements.

Before the final product is released, thorough quality control measures are implemented. This includes inspecting the physical properties, dimensions, and overall integrity of the anti-collision strips. Any defects or inconsistencies are identified and rectified to ensure the strips meet the required standards.

The material selection for anti-collision strips follows certain principles to ensure optimal performance:

The selected materials should possess high impact resistance to effectively absorb and dissipate energy during collisions. This helps to minimize damage to the vehicle and reduce the risk of injury to the occupants.

Durability is a crucial aspect of anti-collision strips. The materials should withstand repeated impacts, harsh weather conditions, and other external factors without losing their integrity or performance capabilities.

Flexibility is essential to allow the anti-collision strips to conform to the shape of the vehicle and absorb impacts from different angles. The selected materials should have sufficient flexibility to adapt to various conditions and provide maximum protection.

In addition to performance characteristics, the material selection should also consider cost-effectiveness. The chosen materials should provide the desired level of protection while being economically viable for mass production.

The manufacturing process and material selection principle of anti-collision strips are crucial elements in ensuring the effectiveness and reliability of these essential vehicle safety components. By carefully selecting suitable materials and following the appropriate manufacturing processes, anti-collision strips can effectively absorb impacts and protect vehicles during collisions.