Phone Number :

07 28, 2023

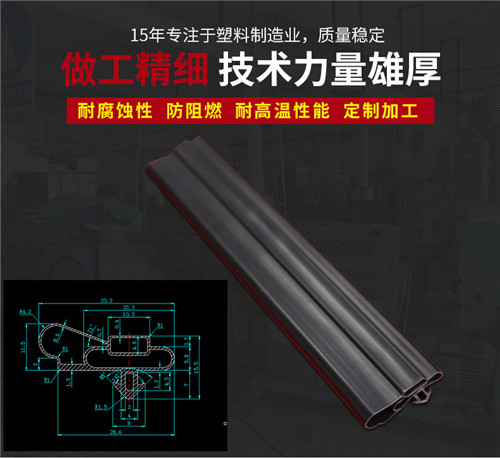

Anti-pollution equipment plays a vital role in preventing environmental harm and ensuring sustainable practices. However, to safeguard such equipment from potential damage and collisions, anti-collision strips are of utmost importance. Serving as a protective barrier, these strips play a crucial role by absorbing force and reducing the impact of collisions. This article highlights the vital role and practical cases of anti-collision strips in the protection of anti-pollution equipment.

Anti-collision strips act as a vital safety measure in the protection of anti-pollution equipment. By serving as a cushion between the equipment and potential colliding objects, these strips minimize the risk of damage caused by accidental collisions. Whether it's heavy machinery or vehicles moving around anti-pollution equipment, the strips provide an additional layer of safety, significantly reducing the likelihood of equipment malfunction or breakdown.

Numerous practical examples highlight the effectiveness of anti-collision strips in protecting anti-pollution equipment. In a manufacturing facility, for instance, where equipment such as pollutant separators and filtration units are required, anti-collision strips ensure that any accidental contact with forklifts or other machinery does not cause damage or compromise the functionality of the equipment. Similarly, in wastewater treatment plants, anti-collision strips installed around clarifiers and aeration tanks prevent collisions during maintenance or equipment movements.

Furthermore, anti-collision strips have also found valuable applications in the protection of air pollution control systems. The use of these strips around electrostatic precipitators and scrubbers reduces the risk of mechanical damage caused by vehicle or equipment movements in industrial settings. The implementation of anti-collision strips in such practical cases demonstrates their effectiveness and indispensable nature in protecting anti-pollution equipment.

Anti-collision strips not only provide protection but also contribute to the overall durability of anti-pollution equipment. In the absence of such strips, the continuous impact of collisions can result in premature wear and tear, reducing the lifespan of the equipment. By absorbing impact and reducing force, anti-collision strips extend equipment longevity, resulting in long-term cost savings. Maintenance costs and downtime due to equipment repairs or replacements are significantly reduced with the implementation of these strips.

Anti-collision strips play a vital role in the protection of anti-pollution equipment. By improving safety measures, preventing damage, and enhancing durability, these strips ensure the continued operation and effectiveness of equipment used to combat pollution. The practical implementation of anti-collision strips in various scenarios showcases their importance and effectiveness in safeguarding anti-pollution equipment. Investing in these strips not only protects the environment but also saves costs in the long run, making them an indispensable asset in the fight against pollution.