Phone Number :

07 27, 2023

In today's industrial environments, the protection of mechanical equipment is crucial for ensuring smooth operations and the safety of personnel. In this regard, anti-collision strips have emerged as an effective solution. This article aims to share engineering practices and insights on the utilization of anti-collision strips in mechanical equipment protection.

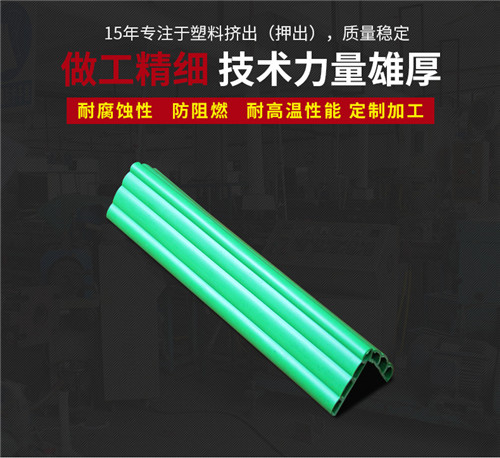

Anti-collision strips are specially designed protective barriers installed on mechanical equipment. They act as buffers to absorb impact, reducing the risk of damage and minimizing downtime. These strips are usually made of durable materials, such as rubber or elastomers, which are capable of withstanding repetitive shocks. The primary function of anti-collision strips is to prevent collisions between equipment, safeguarding their structural integrity.

Proper application and installation of anti-collision strips are critical for their effectiveness. Firstly, a thorough risk assessment should be conducted to identify areas with a high probability of collision. Equipment corners, edges, and frequently traversed pathways are typically prone to collisions and should be given priority. Once the areas are determined, the correct type and size of anti-collision strips should be selected to ensure an optimal fit.

Installation techniques play a significant role in the overall effectiveness of anti-collision strips. The strips should be securely attached using strong adhesive or mounting brackets. Regular inspections must be conducted to ensure the strips are properly maintained and replaced when necessary. Ongoing monitoring of potential collision risks is essential to make any adjustments or additions to the protective measures.

The use of anti-collision strips provides numerous benefits in mechanical equipment protection. Firstly, they significantly reduce the risk of damage to equipment, leading to lower maintenance costs and extended lifespan. Secondly, the implementation of anti-collision strips improves workplace safety by minimizing the potential for accidents and injuries caused by collisions. Furthermore, the installation of these protective measures demonstrates a proactive approach to safety, which can enhance workplace morale and compliance with regulatory standards.

However, there are certain challenges associated with anti-collision strips. It is crucial to ensure that the chosen strips do not interfere with the equipment's functionality or impede the movement of operators. Careful consideration should also be given to the design of the strips to prevent accumulation of dust or debris, which could compromise their effectiveness over time.

Incorporating anti-collision strips as part of mechanical equipment protection is an important practice for industrial settings. By understanding their role, implementing correct application and installation techniques, and recognizing the associated benefits and challenges, engineers and operators can effectively enhance workplace safety and equipment longevity. By prioritizing proper protection measures, we can create a safer and more efficient working environment.