Phone Number :

07 21, 2023

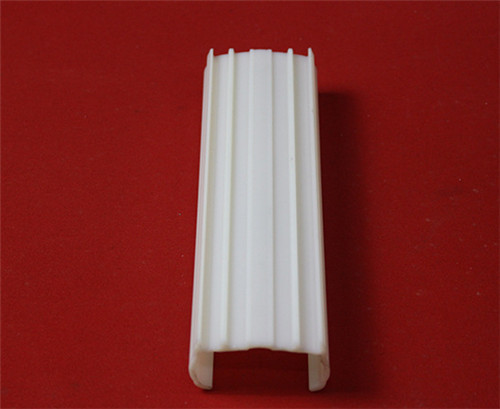

Glass strips for furniture accessories are an integral part of enhancing the aesthetics and functionality of various furniture pieces. This article delves into the manufacturing process and quality standards associated with the production of glass strips, shedding light on the key considerations and steps involved in their creation.

The manufacturing process of glass strips for furniture accessories involves several intricate stages, ensuring the production of high-quality strips that meet industry standards. The following steps outline this process:

a) Glass Selection: The initial stage entails the careful selection of glass, considering various factors such as thickness, transparency, and strength. Specialized glass suited for furniture accessories is chosen to ensure durability and aesthetic appeal.

b) Cutting and Shaping: The selected glass sheets are accurately cut into desired shapes using precise cutting tools and equipment. Cutting techniques such as waterjet cutting or CNC machining are employed to achieve precise dimensions.

c) Edging and Polishing: After cutting, the edges of the glass strips are meticulously smoothed and polished to eliminate any sharpness or roughness. This emphasizes safety and enhances the overall visual appeal of the strips.

d) Tempering and Annealing: To reinforce the strength and durability of the glass strips, they undergo tempering, a heat treatment process. This involves heating the glass to high temperatures and then rapidly cooling it, creating compression on the surface. Subsequently, annealing is performed to remove any stress in the glass, ensuring long-lasting functionality.

e) Quality Inspection: At each stage of the manufacturing process, rigorous quality inspections are conducted to ensure that the glass strips adhere to the required standards. This includes checking for dimensional accuracy, surface integrity, and structural strength.

High-quality standards are imperative to ensure that glass strips for furniture accessories meet safety requirements and offer optimal performance. The following quality standards are commonly followed in the manufacturing process:

a) Thickness and Durability: Glass strips should possess a uniform thickness, ensuring stability and resistance to breakage. They must also meet the specified durability standards, ensuring longevity and withstanding regular usage.

b) Surface Finish: The surface of glass strips should be flawless, free from scratches, marks, or any defects. A smooth and visually appealing finish enhances the overall quality of the product.

c) Tolerance and Precision: Strict adherence to dimensional accuracy is crucial for glass strips to fit seamlessly with the furniture accessories they are designed for. Tolerance levels and precision measurements should be within specified limits.

d) Safety Regulations: Glass strips used in furniture accessories must comply with safety regulations to minimize the risk of accidents. Tempering and annealing processes should be appropriately executed to enhance the structural strength and ensure safe usage.

In conclusion, the manufacturing process and quality standards associated with glass strips for furniture accessories play a vital role in producing superior products that enhance furniture design. By carefully selecting glass, employing precision cutting and shaping techniques, and adhering to rigorous quality inspections, manufacturers can ensure the production of reliable and visually appealing glass strips that meet the needs of the furniture industry.