Phone Number :

07 15, 2023

In the petroleum industry, PVC hoses play a crucial role in facilitating the flow of various fluids. However, these hoses are subjected to unique working conditions, including high temperatures, fluctuating pressures, and exposure to corrosive substances. To ensure their reliability and safety, thorough pressure tests are conducted to evaluate the performance of PVC hoses under such special working conditions.

Pressure testing is a critical component of quality control in the petroleum industry. It is indispensable in verifying the resilience and durability of PVC hoses. The rigorous testing process helps identify any potential weaknesses or vulnerabilities in the hoses before they are deployed in demanding operational environments.

Testing PVC hoses in the petroleum industry presents several unique challenges. Firstly, the hoses must be able to withstand high-pressure conditions to prevent leaks and ruptures. Secondly, the hoses need to maintain their flexibility and structural integrity even when exposed to extreme temperatures. Lastly, the hoses should possess resistance to the corrosive nature of petroleum products, ensuring that their performance remains unaffected over time.

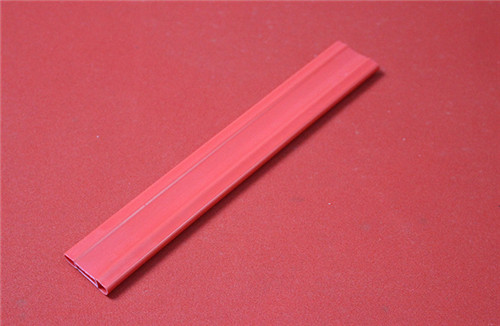

The pressure test of PVC hoses involves subjecting them to stress levels that simulate the working conditions in the petroleum industry. The procedure typically consists of the following steps:

Preparation: The PVC hose is installed in a testing setup, ensuring that all connections are secure and proper safety measures are in place.

Pressurization: Fluid, such as water or air, is pumped into the hose gradually, increasing the pressure systematically to simulate the real-world conditions the hose will encounter.

Observation: Technicians closely monitor the hose for any signs of leakage, deformation, or failure during the pressurization process. This may involve visual inspections, thermal imaging, or non-destructive testing methods.

Testing duration: The hose is typically subjected to the maximum operating pressure for a specified duration to ensure its stability and ability to withstand sustained stress.

Final evaluation: After the test, the hose is thoroughly examined to assess its overall performance. Any signs of damage, including cracks, deformation, or changes in material properties, are carefully documented.

Pressure testing of PVC hoses under special working conditions in the petroleum industry is vital for ensuring their reliability and safety. By subjecting these hoses to rigorous testing procedures, manufacturers and operators can detect any potential weaknesses and make necessary improvements. Ultimately, the goal is to provide durable and resilient hoses that can withstand the challenging demands of the petroleum industry, ensuring smooth operations and preventing any potential hazards.