Phone Number :

07 12, 2023

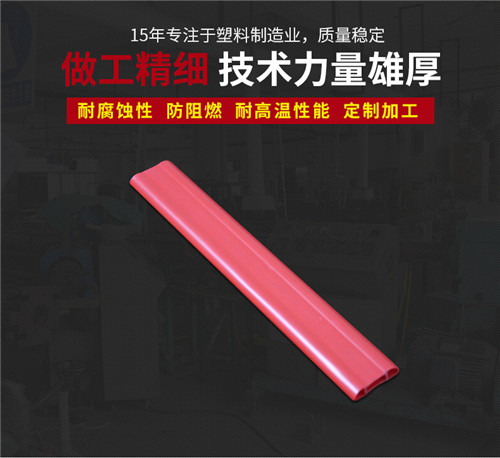

Underground mining operations demand robust and reliable equipment that can withstand harsh conditions and ensure the safety of workers. Among the essential components in this industry, PVC hoses play a crucial role in various applications such as water supply, ventilation, and material conveyance. This article discusses the application and safety evaluation of PVC hoses in the underground mining industry, highlighting their enhanced performance and the measures taken to ensure utmost safety.

PVC hoses find extensive application in underground mining due to their versatility and durability. They are commonly used for water supply to ensure proper hydration and fire suppression. PVC hoses are also employed for ventilation purposes, aiding in maintaining a breathable atmosphere and reducing the risk of harmful fumes and gases. Additionally, these hoses serve for the transportation of materials, including ores, concentrates, and waste products, ensuring the smooth operation of mining activities.

Moreover, PVC hoses are lightweight and flexible, making them easy to install and maneuver in confined spaces. Their resistance to abrasion, corrosion, and chemicals further enhances their suitability for various mining applications. PVC hoses are available in different sizes and pressure ratings, enabling their use in diverse underground mining environments.

The safety of underground mining operations heavily relies on the performance and integrity of PVC hoses. Rigorous evaluations are conducted to ensure their compliance with industry standards and to identify potential hazards. Highly trained personnel conduct regular inspections to assess the hoses' physical condition and identify any signs of wear, leakage, or damage.

Furthermore, PVC hoses undergo structural integrity tests to determine their resistance to internal pressure, external forces, and extreme temperatures. These evaluations verify the hoses' ability to withstand the demanding conditions underground and minimize the risk of accidents or compromised safety. Additionally, chemical compatibility assessments are carried out to ensure that the hoses can safely handle the substances they may come into contact with during mining operations.

In order to enhance the safety of PVC hoses in the underground mining industry, strict procedures and guidelines are implemented. Regular maintenance schedules are established, including cleaning, inspection, and replacement routines, to ensure the optimal functioning of the hoses. Adequate training programs are provided to educate workers about the proper handling, installation, and maintenance of PVC hoses.

Moreover, to prevent potential hazards, PVC hoses are equipped with safety features such as anti-static properties and high visibility colors. These measures help to mitigate the risk of electrical discharge and enhance visibility in low-light conditions, respectively. Additionally, emergency response plans are developed and practiced to address any incidents or failures that may occur, ensuring the prompt and efficient resolution of safety concerns.

PVC hoses have proven to be essential components in the underground mining industry, facilitating various applications and ensuring the safety of operations. Through rigorous evaluation and adherence to safety measures, these hoses exhibit enhanced performance and reliability in demanding underground environments. Utilizing PVC hoses in accordance with established guidelines and maintaining them regularly are vital for the successful and safe execution of mining activities.