Phone Number :

07 09, 2023

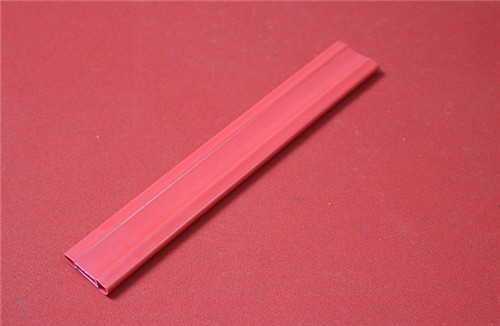

Flame retardant PVC hoses play a crucial role in the building materials industry. They are commonly used in applications such as drainage, ventilation, and conveying various fluids. To ensure the safety of these hoses in potential fire scenarios, rigorous flame retardant performance testing is essential.

Flame retardant performance testing is necessary to evaluate the fire resistance capabilities of PVC hoses. These tests determine how well the hoses can resist ignition, flame spread, and the release of toxic gases. The building materials industry requires hoses to meet specific fire safety standards, making these tests vital for compliance and safety assurance.

Several standard testing methods are commonly used in the building materials industry to assess the flame retardant performance of PVC hoses:

1. Vertical Flame Test: This test evaluates the ability of the hose to resist vertical flame spread when exposed to a predefined ignition source. The time taken for the flame to extinguish, the length of the burnt section, and the release of toxic gases are evaluated.

2. Smoke Density Test: This test measures the amount of smoke emitted by the burning hose material. It helps assess the potential visibility impairment caused by smoke during a fire and aids in evaluating the overall fire safety of the hose.

3. Oxygen Index Test: The oxygen index is the minimum concentration of oxygen required to sustain flame. This test determines the likelihood of a hose sustaining flame by measuring the percentage of oxygen required for flame maintenance in a controlled environment.

Besides the standard testing methods, advanced techniques are being developed to enhance the accuracy and reliability of flame retardant performance testing:

1. Cone Calorimeter Test: This test measures the heat release rate, smoke production rate, and other fire-related parameters of the hose material. The data collected helps researchers and manufacturers improve the fire resistance properties of PVC hoses.

2. Thermogravimetric Analysis (TGA): TGA evaluates the weight loss and decomposition behavior of the hose material when subjected to increasing temperatures. This technique provides valuable information on the thermal stability and degradation of the material.

3. Fourier Transform Infrared Spectroscopy (FTIR): FTIR analysis identifies the different compounds released during the combustion of PVC hoses. It helps in assessing the toxicity of the gases generated and their potential environmental and health impacts.

In summary, flame retardant performance testing is essential to ensure the safety and compliance of PVC hoses in the building materials industry. Through a combination of standard tests and advanced techniques, the fire resistance capabilities, smoke production, and toxicity of the hoses are thoroughly evaluated. These tests help in the continuous improvement of PVC hose materials, ensuring their reliability and effectiveness in preventing fire incidents and minimizing their potential impact on human health and the environment.