Phone Number :

07 09, 2023

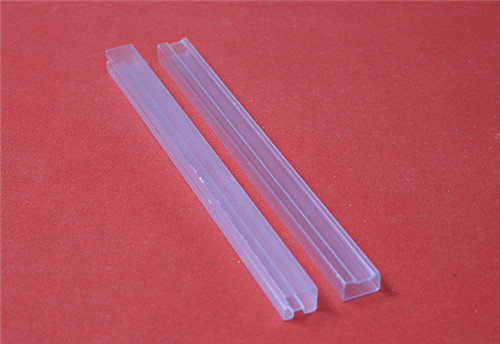

In the manufacturing and handling processes of various industries, the accumulation of static electricity can pose significant risks to both personnel and equipment. In particular, in the transportation and transfer of materials through PVC hoses, static discharge can ignite flammable substances or damage sensitive electronic components. Therefore, it is crucial to conduct thorough research on the antistatic performance of PVC hoses and develop effective countermeasures to ensure safety and minimize operational risks.

Several factors affect the antistatic performance of PVC hoses:

To improve the antistatic performance of PVC hoses, the following measures are recommended:

In conclusion, researching the antistatic performance of PVC hoses and implementing appropriate countermeasures is vital to ensure safety and prevent accidents in various industries. By considering factors that influence antistatic properties and adopting effective measures to enhance conductivity, the risks associated with static electricity can be mitigated. Implementing these countermeasures will contribute to safer operations and protect personnel and valuable equipment.